Finish

Automotive Paint

We bring our panels over to a local auto body shop. They are able to match any color sample we provide them.

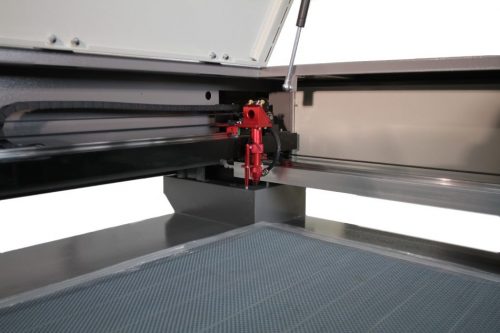

Laser Engraving

We use a 100-watt BOSS Laser machine with a generous 57″ x 37″ engraving platform — ideal for working on our aircraft instrument panels, which typically range from 30″ to 45″ wide.

Every panel we produce is custom laser engraved after it’s been painted, ensuring crisp, high-contrast graphics. Once the panel is precisely aligned under the laser, the fun begins. The result? Clean, professional-looking graphics that bring your instrument panel to life. We’ve received a lot of great feedback about the quality and durability of our laser-engraved designs.

Carbon Fiber Overlay

For those looking for a sleek, high-performance finish, we offer carbon fiber overlays. Here’s how it works:

Each panel is first cut from .063 aluminum. Using the same digital cut file, we then laser-cut the carbon fiber overlay, which features a strong 3M adhesive backing. Because we cut the overlay face-down, we use a mirrored version of the file to ensure a perfect match.

Once cut, the overlay is carefully applied to the cleaned aluminum panel. Afterward, we apply a semi-gloss clear coat to smooth out any microscopic texture and give the surface a uniform, professional finish.

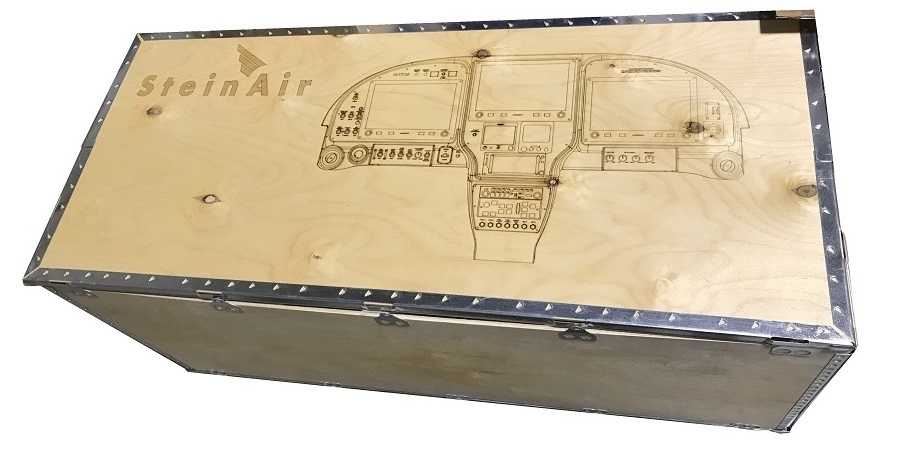

Shipping Crates

with a Custom Touch

All completed panels are securely packed in custom-built 4-foot crates. To add a little extra value (and style), we laser engrave the final panel design onto the crate lid.

This finishing touch has been a customer favorite — many clients have even mounted the engraved lids in their hangar spaces as display pieces.